Him Darji

Him Darji

Step-by-Step Workflow of the Scan to BIM Process

Him Darji

Him Darji

Send Us Your Requirement

In the AEC landscape, one of the most crucial factors is ensuring precision, efficiency, reliability, and safety. Every infrastructure project is built differently, with distinct design plans, processes, and execution. However, the architecture and construction industry isn’t just about creating new infrastructures but also includes renovation, refurbishment, remodeling, and more. While constructing new infrastructure is a hectic, complex process, renovating existing buildings is equally complex. Over time, every building or infrastructure deteriorates for a variety of reasons, such as environmental conditions, improper care, irregular building quality checks, and more.

All this results in decrepit infrastructure. Therefore, constructing the building isn’t the end goal; it’s also about properly maintaining it to extend the project lifecycle and keep it functional. As a matter of fact, the historic infrastructure of the nation is carefully restored and renovated at a regular timeline for accurate maintenance of the structure in its original form. This shows the importance of renovating existing buildings and integrating them with new materials and technologies to increase longevity. Therefore, in the AEC realm, renovation and remodeling are critical processes supported by a significant technology called scan-to-BIM.

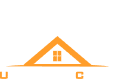

In the advanced and revolutionized landscape of the architecture and construction sector, a variety of technologies have transformed reality. Building information modeling services have played a massive role in this paradigm shift. Traditionally, AEC experts used to manually measure, draw, and construct the entire project, including renovations. This took a long duration, led to erroneous results, costly rework, and more. BIM workflow today brings enhanced project results with the ability to offer a 3D digital representation of the project.

Today, in the vast market, building information modeling has become a go-to tool for architects, engineers, designers, and other professionals. Similarly, for renovation and reconstruction, BIM plays a vital role, replacing the traditional methods. Renovation and reconstruction projects are time-consuming, complex, and labor-intensive tasks that demand precision and quality. Here, Point cloud to BIM modeling services becomes a game changer that enables AEC professionals to renovate the infrastructure with accuracy and within the timeline.

In the vast landscape of architecture and construction, the BIM workflow stands out for several reasons, including the use of advanced technology for scanning, precise annotation, integration into the BIM model, and, finally, structural renovation on the ground. Explore in detail the Scan-to-BIM service and its intricate process to better understand it.

Create Accurate Renovation Project with Point Cloud to BIM

Get a Quote

Insights into Laser Scanning to BIM

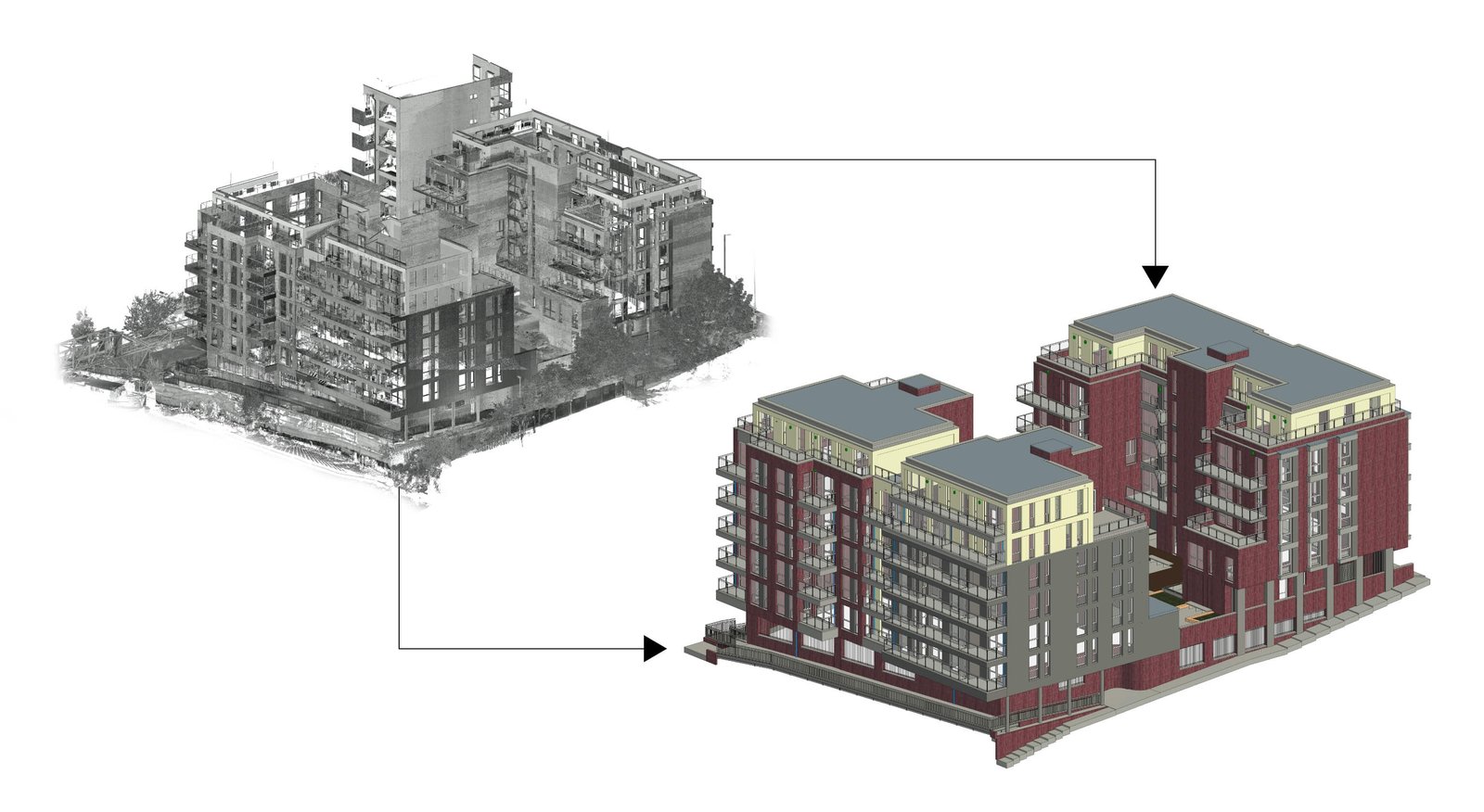

In the vast and evolving fields of architecture and construction, the key factors in project success are accuracy and efficiency. As discussed, AEC is not only about constructing new projects but also about renovating existing buildings, remodeling, and refurbishing to maintain the infrastructure. While traditional or manual approaches cannot deliver precise results, the AEC landscape is transforming with advances in technology that enhance the overall process, minimize errors, accelerate it, and more. Therefore, the point cloud to Revit model here plays a significant role for AEC experts, allowing the use of advanced tools to scan infrastructure and integrate it into 3D BIM models.

This process involves 3D laser scanning technology, BIM modeling services, and expertise to execute the entire process. It may sound easy, but it is a complex procedure that demands knowledge, expertise, proper tool use, and more. As a matter of fact, the digitized transformation process allows AEC professionals to create an accurate, data-rich digital twin of the existing infrastructure.

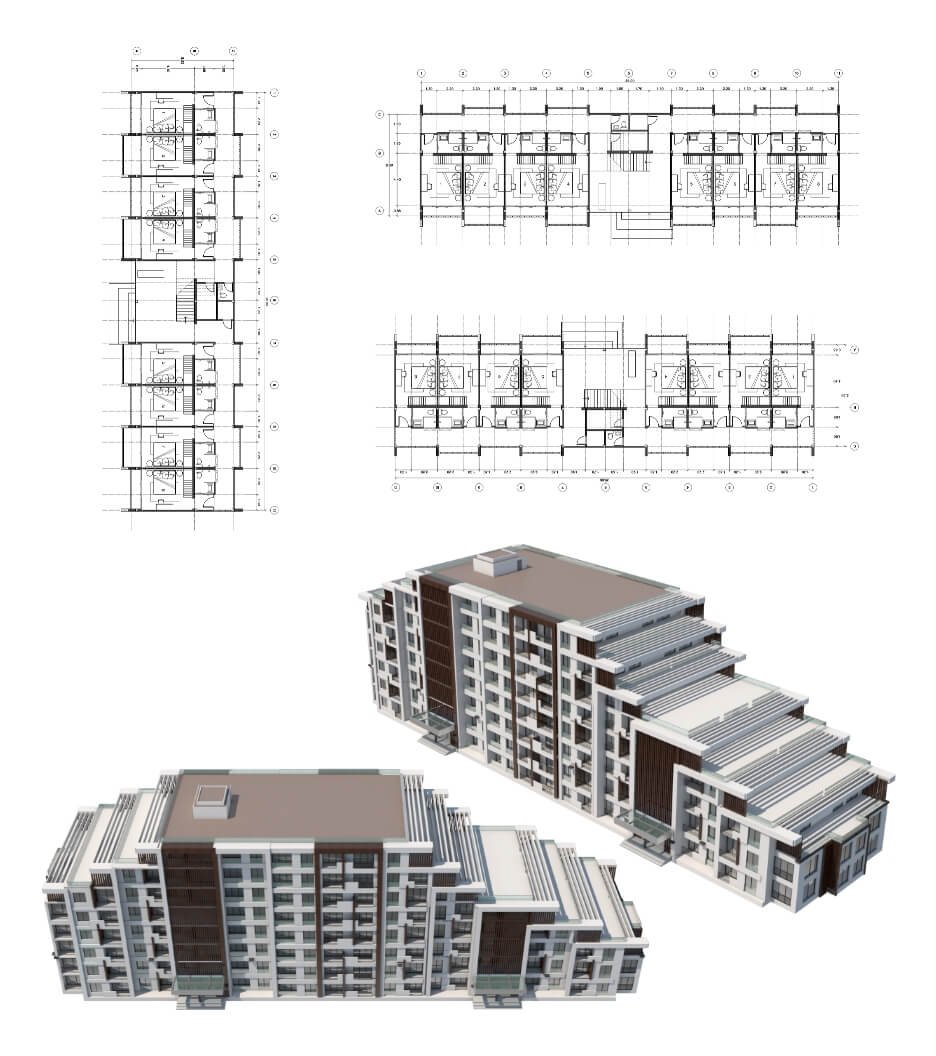

This further enables architects, engineers, and other construction professionals to renovate the area or entire building. In simple terms, BIM modeling from point clouds is the process of converting point cloud data captured by 3D laser scanners or other technologies into building information modeling (BIM) models, which are rich not only in geometric data but also in details about building components, materials, and properties.

Laser scans, photogrammetry, and other tools are used to scan the required area or the entire building. Manual processes involve manual measurements that can be wrong due to human error, are time-consuming, cannot reach small angular areas that are not visible to the naked eye, and more. As a matter of fact, Point cloud to BIM modeling services provide holistic solutions to the above challenges and transform complex processes with the help of laser-scanning tools and other software.

Typically, laser scanning techniques collect point cloud data from the area or building, which is then integrated into the BIM model that digitally represents the building’s physical and functional characteristics. Being a crucial workflow in the architecture and construction sector, its application is widely spread in different aspects, as follows;

Scan to BIM Applications

Renovations and Restorations

Facility Management

Construction

Design

Disaster Recovery

- Renovations and Restorations: scan to BIM technology provides an accurate “as-built” model of existing conditions, which is crucial for remodeling and renovation projects.

- Construction: a scan-to-BIM workflow enables more accurate planning, supports clash detection, and improves overall efficiency.

- Facility Management: Creates a digital twin for maintenance, asset management, and operations throughout a building’s life. This helps in maintaining the infrastructure life and increases longevity.

- Design: Allows architects and engineers to design new additions or modifications with full knowledge of the existing structure, minimizing errors and improving decision-making.

- Disaster Recovery: Provides a high-accuracy record of a building’s condition after an event, which is invaluable for reconstruction efforts.

These are the key applications of point clouds in BIM modeling services, which enhance renovation and restoration project processes. The technique of laser scanning integrated with BIM modeling provides an improved approach for renovating hard-to-reach areas.

Moreover, BIM modeling services also enable improved communication, collaboration, 3D visualization, and early clash detection, resulting in quick resolution and the desired repairs to the infrastructure. Not just this, but 3D model creation from scans provides a long list of advantages. Discover them in detail.

Advantages of Scan to BIM Workflow

For accurate restoration and repair of existing structures, point cloud-to-BIM is a key technology. As discussed above, it has become a prominent approach, dissolving the need for traditional methods. Scan to BIM is a concept that eliminates the gaps caused by human error, delivers precise results, and offers a data-driven approach that aligns with real-world conditions, leading to improved coordination and less rework. Not just this, but BIM modeling from point clouds offers various benefits in architecture, engineering and construction, as follows:

Key Advantages of Scan to BIM

As-Built Truth

High Fidelity

Single Site Visit

Clash Detection

Historical Documentation

Reduced Rework

Faster Data Capture

Predictable Modeling

Facility Management (FM)

Shared Understanding

Contextual Design

- As-Built Truth: The laser scanning captures millions of data points from the existing infrastructure that creates a geometrically precise, comprehensive digital record of existing conditions. This virtually eliminates the errors inherent in manual measurements.

- Reduced Rework: One of the key features of the BIM model is minimizing errors. By starting with a highly accurate BIM model, design clashes and assumptions about existing conditions are minimized, saving time and costs associated with field verification and costly rework during construction.

- High Fidelity: Capturing intricate and complex geometries (like curved surfaces, historical details, or complex pipe runs) that would be difficult or impossible to measure manually.

- Faster Data Capture: A site can be scanned significantly faster than it can be measured manually that reduces on-site time and minimizes disruption to ongoing operations.

- Single Site Visit: A single, comprehensive scanning session can capture all necessary data, reducing the need for multiple site visits to address missed measurements.

- Predictable Modeling: The detailed point cloud data allows modelers to work efficiently off-site with minimal ambiguity, speeding up the modeling process.

- Clash Detection: An accurate as-built BIM model is essential for running clash detection checks against new design elements (e.g., new MEP systems) and identifying conflicts before construction begins.

- Facility Management (FM): The resulting laser-scanned-to-BIM model, especially when built to a high Level of Detail (LOD) and including non-geometric data, becomes a rich database for future Facility Management. It aids in maintenance, space planning, and asset tracking.

- Historical Documentation: It provides an invaluable, permanent digital record of heritage or historical structures for preservation, study, or restoration efforts.

- Shared Understanding: The 3D model and the underlying point cloud provide a clear, unambiguous visualization of the existing site conditions for all stakeholders, improving communication and decision-making.

- Contextual Design: Designers can place their new proposals directly into the accurate digital context of the existing building, leading to better-informed and integrated designs.

3D model creation from scans is not a technology but a significant and comprehensive approach for the AEC landscape. As it aims to reduce manual errors and accelerate the process, these benefits can only be realized if the scan-to-BIM process steps are followed accurately. As a vital part of the AEC realm, this approach is guided by an intricate process that delivers efficient, precise solutions. Discover the process in detail.

Scan to BIM Workflow in Detail

As briefly discussed, the significance and benefits of laser scanning technology and its integration into BIM modeling services are discussed. Understanding the scan-to-BIM process is key to reaping the benefits mentioned above. Once the existing infrastructure is scanned, the point cloud data is initially cleaned, aligned, and registered. Skipping this key part can compromise the accuracy of the 3D BIM model, leading to misaligned results. Therefore, strictly adhering to the scan-to-BIM process is a solution by partnering with the Scan to BIM company. Let’s focus on the process of point cloud-to-BIM modeling services in detail.

Step 1: Project Planning and Requirements Definition

- Define Objectives and Scope: What is the final model going to be used for? (e.g., renovation design, structural analysis, facility management, clash detection). This dictates the entire process.

- Establish Level of Detail (LOD): The LOD specifies the geometric and non-geometric (data) information to be included in the model. A higher LOD (e.g., LOD 400 for fabrication) requires more scanning and modeling effort than a lower one (e.g., LOD 200 for conceptual design).

- Determine Accuracy Tolerances: Define the maximum acceptable deviation between the final BIM model and the raw scan data, which can range from a few millimeters for historic details to a few centimeters for general facility management.

- Site Assessment & Scan Plan: A pre-scan walk-through helps to identify site-specific challenges that are not visible to the naked eye, for example, complex piping, high ceilings, and security access. It enables the planning of optimal scanner locations to ensure complete coverage and minimize “blind spots.”

Step 2: 3D Laser Scanning and Data Acquisition

- Site Preparation: Clear any temporary obstructions that could interfere with the scanner’s line of sight or create unnecessary data noise (e.g., temporary furniture or construction clutter).

- Scanner Deployment: High-precision 3D laser scanners(using LiDAR—Light Detection and Ranging—technology) are placed on tripods at various locations around the site.

- Data Capture: The scanner emits millions of laser pulses, measuring the distance and angle to every surface it hits. Each return signal is recorded as a single data point with precise X, Y, and Z coordinates. The collection of these millions of points is the Point Cloud. Scanners often also capture High-resolution photographic images to colorize the point cloud, improving visualization.

- Field Quality Control: The team verifies on-site that all required areas have been scanned and that the data is clean enough before leaving the site.

Step 3: Point Cloud Processing and Registration

- Registration: Since each scan position captures only a part of the space from its unique perspective, the individual point clouds must be accurately aligned and merged into a single, unified coordinate system. This is called Registration and is typically performed using specialized software such as Autodesk ReCap or Leica Cyclone.

- Cleaning and Filtering: The registered point cloud often contains unwanted noise—data points from temporary objects, people who walked through the scan, reflections, or external clutter. These spurious points are filtered out to leave a clean, clear representation of the permanent building structure.

- File Export: Once the final, cleaned, and registered point cloud is exported in a format compatible with the BIM modeling software (e.g., `.rcp`, `.e57`, or `.pts`).

Step 4: BIM Model Creation (Modeling)

- Import into Revit BIM Software: After decluttering the points collected through laser scanning, the processed point cloud is imported into BIM authoring software, most commonly Autodesk Revit or ArchiCAD.

- Modeling Elements: BIM modelers use the point cloud to precisely trace and create intelligent, parametric building elements at the required LOD. The process typically starts with major structural components (columns, walls, floors, roofs) and then moves to architectural features (doors, windows, stairs, millwork).

- MEP Modeling (if required): For higher LOD projects, the Mechanical, Electrical, and Plumbing (MEP) systems (ductwork, conduits, pipes, fixtures) are also modeled by extracting their geometry from the point cloud.

- Adding Non-Geometric Data: Information beyond geometry, such as material type, product specifications, manufacturer data, and fire ratings, is embedded in BIM objects, making them an information model rather than just a 3D graphic.

Step 5: Quality Assurance (QA) and Model Validation

- Geometric Accuracy Check: It is a significant step in the process as it brings precision for AEC professionals to enhance the complex approach. The completed 3D BIM model is overlaid with the original point cloud to generate a deviation analysis report (also known as a “heat map”). This report visually highlights areas where the modeled geometry deviates from the scanned points by more than the specified tolerance, enabling targeted corrections.

- LOD and Data Check: The model is audited to ensure all required information (both geometry and embedded data) has been included as per the initial project plan.

- Clash Detection: If multiple systems (Architecture, Structure, MEP) were modeled, a clash detection analysis is run in software such as Autodesk Navisworks to identify interferences or collisions between elements (e.g., a duct running directly through a structural beam).

Step 6: Final Deliverables and Integration

- Model Handover: The native BIM file (e.g., Revit. rvt) is delivered, along with the registered point cloud files, the QA/deviation report, and any necessary 2D drawings (floor plans, sections, and elevations) generated from the model.

- Project Integration: The client integrates the “as-built” BIM model into their overall project workflow. This accurate digital twin becomes the single source of truth for planning renovations, coordinating new design elements, or informing facility maintenance systems.

The scan-to-BIM process steps fundamentally improve design and construction outcomes by providing an unparalleled level of certainty about a building’s existing conditions, minimizing costly field errors, and reducing overall project timelines.

In the End

Point cloud-to-BIM modeling services have been a game-changer in the AEC sector for renovation projects. Adhering strictly to the process helps produce an accurate and efficient 3D model.