Rahul Dogra

Rahul Dogra

Evolution of Structural Steel Detailing: From 2D CAD to 3D BIM

Rahul Dogra

Rahul Dogra

Send Us Your Requirement

The era of architecture and construction has seen a massive wave of revolution in terms of approach, services, and technology. With constant development in technology and innovation, AEC has experienced various methodologies that serve a more enhanced and accurate process. Due to the complexity and lengthiness of any infrastructure project, the construction sector entails multiple stages as well as aspects. Although precision and efficiency remain the key to the project’s success. Technologies over time have improved accuracy as compared to traditional days. Today, the AEC landscape has moved towards digitalization, which offers multiple benefits, simplified processes, accurate outcomes, and a curve of creativity for modern architecture. With that, the architecture and construction industry is rapidly adopting new technologies to serve the intricate project design. This has resulted in immense demand for precision and efficiency in order to ensure the modern architecture entails the client’s requirement and functionality of the infrastructure.

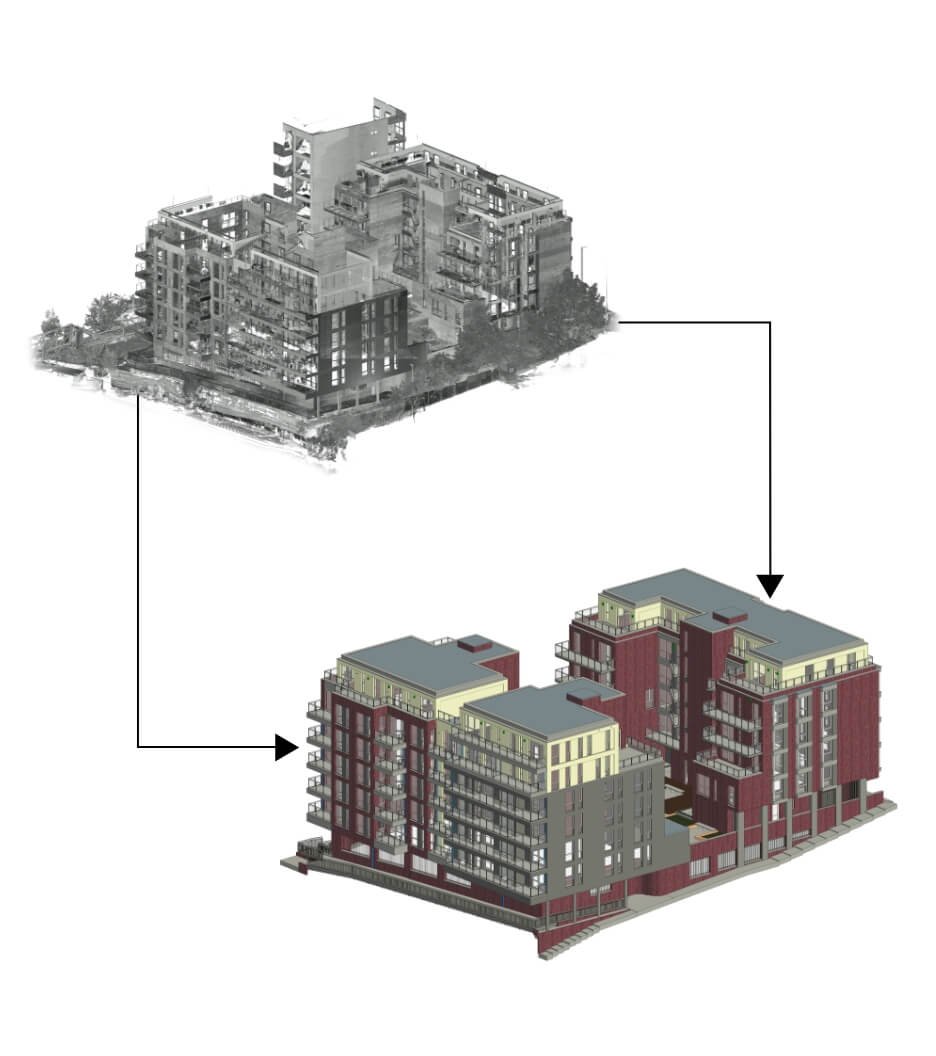

As the field of architecture has various stages, BIM has become one of the paramount technologies for architects, engineers and other professionals. As compared to earlier days of construction, BIM services have become an essential tool for AEC professionals to ensure project accuracy, efficiency, and reliability. Moreover, this indispensable tool is utilized at every stage of the project as it offers a 3D digital representation of the structure that leads to better results and reduced errors. Before BIM, CAD brought a significant revolution, allowing professionals to shift from paper-based sketches or blueprints to computer screens with 2D views. With time and expansion, CAD to BIM transformation became a need of an hour for several reasons, including the limitation of CAD in complex projects, the rising state of technology, the introduction to modern architecture, and much more.

Since there are multiple stages in a construction project, the structural stage holds an immense significance. Structural BIM services play a crucial role in ensuringStructurally BIM services play a crucial role in ensuring the infrastructure can withhold the intended load. This helps professionals ensure the accuracy of structural components, withstand environmental or external conditions, solid framework, and more. An infrastructure goes beyond just interior and exterior. If the structure isn’t strong or unable to bear the intended load, the structural framework isn’t strong. As a matter of fact, the structural framework is the backbone of any construction project, ensuring the resilience of environmental factors. In this particular stage, structural steel detailing holds crucial importance. To get into details, let’s understand what steel detailing is and why there is a need to shift from CAD to BIM.

Precise Steel Structure Detailing with BIM Experts

Get a Quote

Introduction to Structural BIM Steel Detailing

As discussed, the industry is rapidly changing with advancements in technology. CAD services brought revolution in the AEC realm; however, BIM quickly became a groundbreaking technology. There was a drastic shift from CAD to BIM services in the industry, enabling professionals to overcome the limitations of CAD and bring insightful outcomes with 3D digital representation. As a matter of fact, architectural designs on the modern horizon are becoming complex. Hence, the immense requirements for shift resulted in better outcomes. Moreover, this transformation has helped in structural detailing services, resulting in enhanced outcomes. Steel detailing ensures each beam, column, and joint fits precisely at the intended position, offering strength and ability to withstand the load along with external forces.

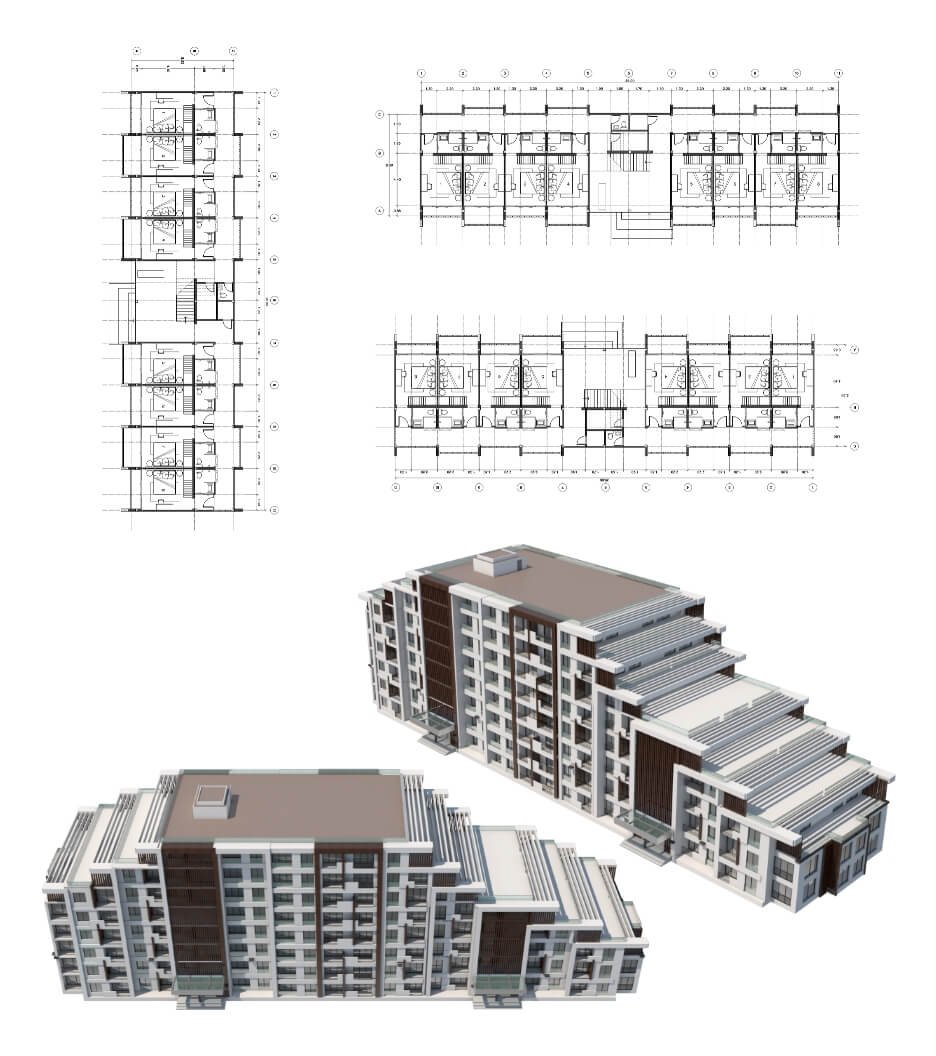

Typically, this process entails detailed 2D drawings and plans for fabrication purposes. The structural drawing encompasses each component’s accurate dimensions, materials, and joints. A detailed set of drawings helps fabricators and contractors to accurately fit the beams and columns. As a matter of fact, over the years, the evolution of steel detailing has allowed professionals to achieve precision, safety, and compliance in the structural BIM stage. From 2D CAD to 3D BIM models, fabricators and contractors can easily maintain a level of accuracy in modern structure design. Since CAD has its limitations, BIM technology allowed experts to enhance the accuracy along with construction documentation.

Traditionally speaking, steel detailers, fabricators, and other professionals used 2D drawings for planning and construction. Due to certain limitations of 2D CAD, BIM for steel structures emerged as a revolutionary modeling process, improving collaboration, communication and efficiency. Let’s explore in detail why transformation in CAD to BIM services served as a paramount of success in the steel detailing process.

Revolutionary Shift from 2D CAD to 3D BIM

Before BIM modeling services were introduced, CAD was a significant technology for architects, engineers, and other professionals. Through an intricate process, 2D models had their own limitations that were becoming an obstacle in quality and precision for steel detailers and fabricators. The 2D CAD drawings entailed floor plans, cross sectors, and another set of details; however, they lacked the ability to represent the 3D view of the components and other insights into the structure. While CAD service provider ensured to offer a digital approach to overcome the manual drafting process, 3D BIM services brought a more enhanced and realistic view of components and elements of structural steel. CAD drawings offered accuracy but lacked information and enhanced precision for complex architectural projects. Moreover, 2D CAD had a significant limitation that hindered the project accuracy, following are;

- Limited collaboration

- Lack of visualization

- Erroneous outcomes

- Lack of detailing or information

- Higher chance of rework & delays

Therefore, as technology advanced and BIM quickly became a groundbreaking approach, steel detailers, and fabricators were able to offer more accurate detailing, a lesser scope of errors, and a collaborative nature among different AEC professionals. In fact, BIM workflow for structural engineers, fabricators, and detailers improved the process, ensured compliance with building codes and industry standards, and offered high quality. Here’s how BIM has revolutionized the steel detailing process.

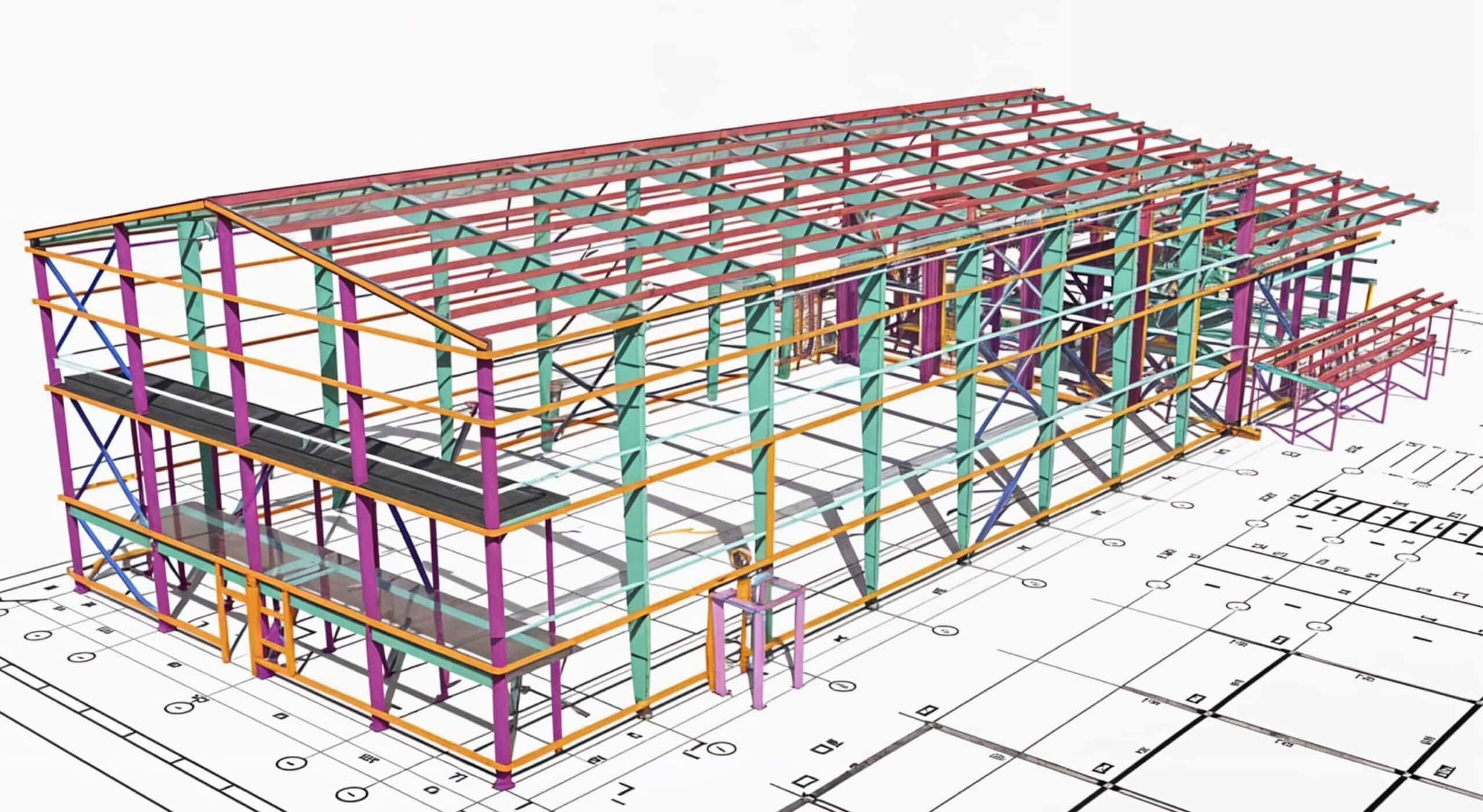

BIM Revolution in Steel Detailing Services

Building information modeling represents a paradigm shift in structural steel detailing. Unlike 2D CAD drawings, BIM technology goes beyond just creating drawings for professionals; it also provides a detailed 3D digital representation of a facility’s physical and functional characteristics enriched with data. As a matter of fact, CAD 2D shop drawings lacked the ability to showcase the components in 3D view, which impacted the level of precision in the detailing process. Additionally, the groundbreaking technology identifies potential clashes or flaws, ensuring each component and element fits together perfectly. BIM for steel structures brings consistency in production of shop drawings while a team of professionals streamline the intricate process. Following are some of the major benefits of BIM in the steel detailing process.

Benefits of BIM in the Steel Detailing Process

Parametric Modeling

Fabrication and Erection Data

Visualization and Simulation

Clash Detection

Improved Collaboration

Life Cycle Management

Quantity Takeoff and Cost Estimation

- Parametric Modeling: BIM technology uses parametric modeling, which allows professionals to modify one element while other sets of the same components are automatically updated. This helps reduce the time, cost, and effort involved in rework while ensuring that the structural model is precise and has a solid framework.

- Clash Detection: Errors or clashes between different components are common; however, overcoming them is a must for the success of the project. BIM services foster quick clash detection in the process among structural components. This helps identify possible errors or conflicts between structural steel elements and other building systems, such as MEP disciplines and architectural components, resulting in minimized rework and smoother construction. Early detection of errors allows professionals to quickly bring resolution without compromising the structural framework integrity.

- Fabrication and Erection Data: Steel detailers, fabricators, and other professionals require detailed insights into components and materials. With the help of 3D BIM services, professionals can have hands-on, precise, and detailed fabrication and erection information, including material properties, dimensions, and connection details. This information is also utilized further for construction documentation at a later stage.

- Improved Collaboration: CAD technology improved communication and collaboration, although to a certain limit. With BIM, AEC experts can enable improved collaboration and communication to stay on the same page. This facilitates information sharing that results in reduced communication, enhances project workflow, and improves the accuracy of the overall structural BIM process.

- Visualization and Simulation: Within the 2D CAD drawing, the major limitation was the visualization. AEC professionals were limited in viewing the components or elements in a 2D format that lacked high precision and information. On the other hand, 3D modeling in structural engineering enables steel detailers, engineers, and fabricators to visualize the steel structure realistically, aiding in design review and communication. It also supports the simulation of construction sequences, enabling better planning, risk mitigation, and overall precision in the construction project.

- Quantity Takeoff and Cost Estimation: Resource and material allocation is a significant aspect of accurate structural detailing. The level of detailing to 400 BIM model enables professionals to stay updated for accurate quantity takeoffs and cost estimation, which drives better project budgeting, less material wastage, and crucial time in resource management planning.

- Life Cycle Management: BIM work doesn’t end here once the construction is completed. Since 3D BIM models are enriched with precise data on the structure and its elements, they offer accurate facility management, allowing professionals to have updated structural information for future renovations or repairs. In fact, with the CAD work approach, experts lacked accurate documentation for future reference.

These are some of the benefits of CAD to BIM transformation, which fosters improved communication, collaboration, accuracy, and efficiency in steel detailing services. As discussed, structural BIM services are the backbone of any infrastructure. Implementing precise steel detailing is essential for success. Therefore, specialized software and technologies are required to produce accurate results. Let’s explore some of the most efficient technologies that support structural steel detailing services.

Reliable Softwares for Steel Detailing

In the field of architecture and construction, technologies and software have enabled professionals to work accurately and meticulously, offering precise results. Furthermore, AEC is enriched with a plethora of softwares for different services. However it requires specialized skills and software proficiency for seamless digital workflow. Hence it is vital to hire BIM consulting companies who are proficient in offering BIM steel detailing services.

Team of professionals understand the intricacy of the project and ensure to offer the most high quality and accurate outcomes. As a matter of fact, outsourcing BIM companies have access to the latest technology, tools and software that becomes an added benefit. Therefore, here’s a most precise and updated list of softwares that are available for BIM steel detailing.

Softwares for BIM Steel Detailing

Tekla structures

SDS/2

ProSteel

Advance Steel

AutoCAD structural detailing

- Tekla structures: It is one of the most well known software for automated steel detailing solutions. Due to its powerful 3D modeling and efficiency in managing complex structural design, professionals in AEC widely use it. Moreover it is also compatible with other softwares, ensuring the accuracy and efficiency in structural components such as beams and columns fit perfectly in the design.

- AutoCAD structural detailing: Another significant software is AutoCAD structural detailing which is specially designed for steel detailing. The softwares features easy use, generated data rich detailed drawings and offers a high level of precision for structural engineers and contractors.

- SDS/2: SDS/2 software brings comprehensive features and tools to ensure the precision in steel detailing that also includes fabrication and 3D modeling. It is another technology that is widely adopted by structural engineers and detailers for quality, accuracy and efficiency.

- ProSteel: This software brings a holistic approach and ensures to streamline the entire project with flexibility and scalability. Additionally it manages large complex structural designs efficiently and offers innovative results for fabrication.

- Advance Steel: Advance steel provides tools for intricate steel detailing and fabrication. However this particular software demands for familiarity with the features and tools to bring out the best results. It also offers compatibility with other softwares enriched with information.

These are some of the key softwares offering BIM for steel structures enabling AEC experts to bring precise results. Moreover utilizing these above mentioned requires significant skills and knowledge while having expertise in the detailing process. It is advisable to outsource steel detailing services by renowned BIM consulting companies, offering tailored and accurate solutions.

In the ever growing landscape of AEC, outsourcing is a common and profitable investment. UniquesCADD is a well known outsourcing BIM company in India offering extensive BIM and CAD services. Our experts provide advanced solutions for structural steel services with implementation of the latest cutting edge technologies and softwares.

Ending Note

Success of any construction project depends on how solid the structural framework is. This includes efficiency in steel detailing, ensuring each structural component fits perfectly. Hence CAD to BIM services plays a pivotal role in offering most precise outcomes for simple and complex structures.