Mahipal Jadeja

Mahipal Jadeja

Shop Drawings vs. Design Drawings: Key Differences to Know

Mahipal Jadeja

Mahipal Jadeja

Send Us Your Requirement

The architecture and construction realm is consistently growing with precision, efficient solutions, and sustainable practices. Technology and innovation are primary factors that have pushed the AEC sector to reap the benefits of a streamlined and accurate approach. Traditional methods no longer serve their purpose in the digital and modern era, as the demand for precision, reliability, sustainability, safety, and other qualities has increased among the public.

With the significant integration of technologies such as building information modeling, Revit families, and others, the work approach to the construction process has improved; however, drawings, designs, and blueprints still play a crucial role. Before 3D BIM modeling is made, a static, detailed, and generic drawing of the project is curated. This acts as a blueprint to understand the idea, concept, and design strategy for the infrastructure. Moreover, such blueprints help minimize significant costs and errors.

Drawings are the visual elements that enable AEC professionals to gain a quick insight into project planning. For accuracy in modern construction, drawings are the initial step in the planning and designing stage, as they help to bring the idea to paper. Moreover, these drawings also indicate whether the planned design is feasible and if it requires any changes according to the project’s requirements.

Usually, in the construction landscape, complexity depends on the design; accurate drawings bring efficient planning and design completion. For project success, drawings lay the foundation for the concept or idea; however, these simple drawings aren’t enough for successful project modeling. These drawings are further classified with technical details, labeling, dimensions, and other relevant information, enabling AEC professionals to gain a deeper understanding.

In the vast world of architecture and construction, shop drawings and design drawings are key aspects in any project. One is the foundational factor, and the other is detailed and technical sketches that offer precise information for 3D modeling and further stages of development. Design drawings, also known as construction drawings and shop drawings, have their advantages, but they are crucial as each type offers distinct benefits.

Moreover, the importance of drawings in the AEC realm enables professionals to design and manufacture with precision for fabrication. Architectural, structural, and MEP shop drawings services are the crucial aspects. On the other hand, design or construction drawings facilitate a detailed understanding of the concept. The difference between the two is thin yet vital; therefore, let’s examine each of their unique characteristics, roles, benefits, and more to ensure clarity.

Upscale Architecture Projects with Accurate Shop and Design Drawings

Let’s Talk

Key Insights to Design Drawings in Construction

Architecture and construction projects initially require drawings that depict the idea and concept. Typically beneficial for the planning, designing, and fabrication stage, blueprints or sketches are a vital part of the process. As briefly discussed, the construction industry consists of two types of drawings, each with a significant role to play. In the field of AEC, where precision and efficiency are paramount to project success, drawings are evident in the initial stages, allowing architects, engineers, and contractors to accurately understand the project design. During the initial stages, the design drawing is the foremost step.

Typically, these are technical illustrations or visual sketches that help in communicating the plans for a project, visualize the idea into a representation, enabling AEC professionals to construct with precision. As a matter of fact, design drawings are aesthetic visuals for communicating the plan and also include various types of drawings, such as concept, schematic, and detail drawings, and detail specific elements like structural elements, MEP components, architectural, and more. Architectural drawings, or per se design drawings, have three main purposes, as follows;

- Communication: Design drawings are a key aspect of communication for AEC professionals, as they depict the designer’s vision to guide other professionals involved in the project.

- Development: Initially, curated drawings are used for development, providing a foundation for detailed plans that allow professionals to refine them accordingly.

- Guidance: Drawings for projects provide architects, engineers, and contractors with information to guide actual construction or fabrication processes, enabling them to match the design intent.

The above-mentioned points reflect the importance and purpose of the construction drawings. It offers accuracy in the subsequent process and helps architects, as well as BIM experts, to curate precise 3D BIM models. Design drawings also encompass various types that aid in fulfilling the intent of AEC professionals. The following are some of the key types of drawings for the initial stage of the construction.

Various Types of Drawings in Construction Projects

Concept drawings

Detailed drawings

Electrical drawings

Assembly drawings

Section drawings

Schematic drawings

Structural drawings

Plumbing drawings

Elevation drawings

As-built drawings

As design sketches or blueprints are vital for the fabrication and design stage of the project, they serve as an early stage of development, communicating the design intent and concept. Not only does it clarify the intent of design, but it also serves as a universal language for architects, contractors, and other professionals. The following are primary benefits of design drawings;

- Enhanced safety

- Detailed specification

- Translation of ideas and concepts

- Quality assurance

- Streamlined production

- Better communication

- Minimized errors

- Efficient project development

Design or construction drawings aren’t the only type, but it go into detailed and technical shop drawing services. Explore further in detail about shop drawing and understand what is the key difference between design drawing and shop drawing.

Overview of Shop Drawing Services

Architecture and construction are industries where technological advancements and consistent growth are integral. To accurately complete the construction project with precision and efficiency, drawings play a significant role. From the design stage to fabrication, blueprints or sketches help AEC professionals convey design intent, understand the concept, and enable architects and engineers to proceed accurately with the process.

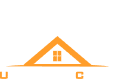

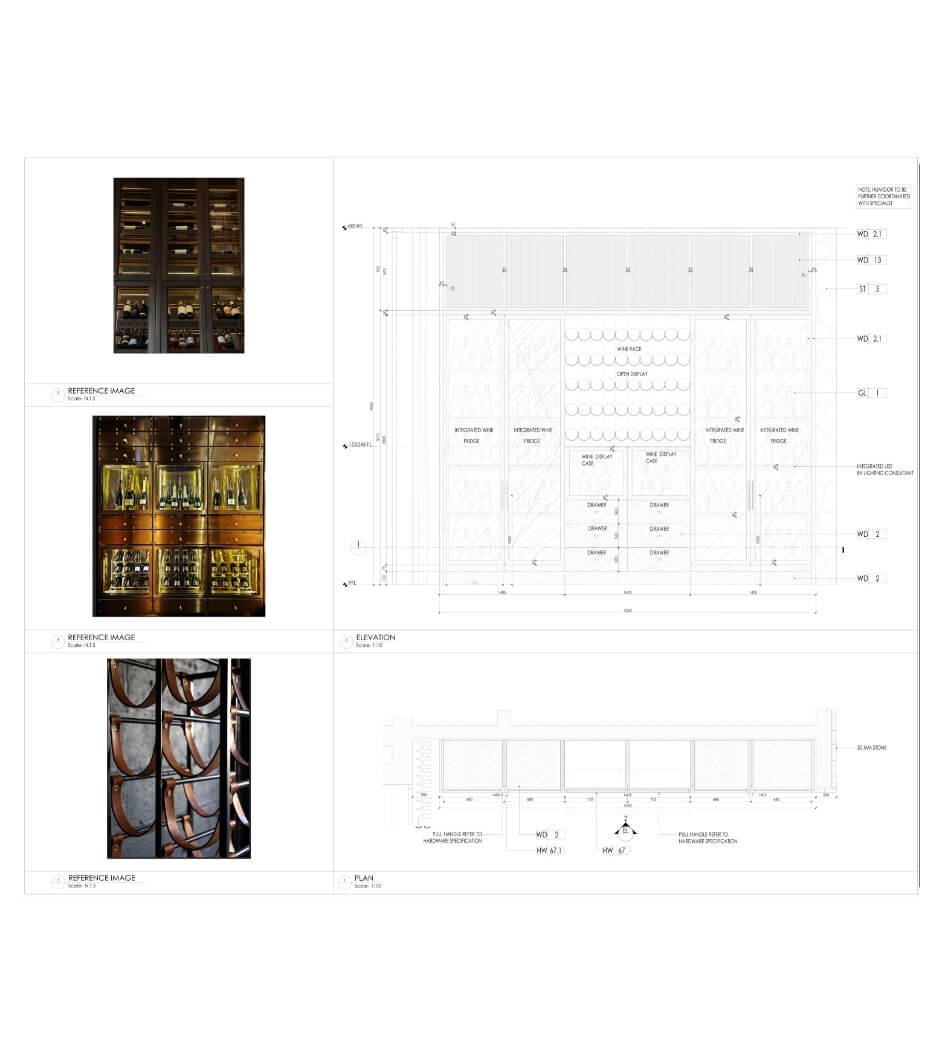

Detailed or technical drawings are a pivotal part of any construction project, with specifications for every professional involved in the project. Technical, detailed drawings in construction are called shop drawings, which are essential for structural, MEP, and other elements. As a matter of fact, shop drawings involved specific details, dimensions, fabrication details, component installation, such as structural elements, building systems, custom-made products, and more.

Moreover, shop drawings enable us to bridge the gap between the design concept and the actual construction process, providing a technical representation of project execution. This represents the importance of shop drawings for AEC projects, as they include information about materials, dimensions, tolerances, requirements, and critical details for contractors and fabricators. Moreover, shop drawings in architecture and construction are complex in nature as they require intricate detailing.

This demands professional expertise, knowledge, software knowledge, and more. Therefore, outsource shop drawings is a holistic solution for AEC firms to get hands-on, precise, detailed technical sketches. Typically, the shop drawing approach is vital for construction, fabrication, and manufacturing due to a variety of reasons, such as;

- Precise communication and coordination

- Detailed representation

- Fabrication guidance

- Quality control

- Early clash detection

The above-mentioned reasons also reflect the beneficial outcomes in the AEC realm. However, in the architecture and construction industry, different stages of the project require different shop drawings, such as

- Architectural shop drawings

- Structural shop drawings

- MEP shop drawings

- Millwork shop drawings

For different stages, shop drawings help represent the detailed technical aspects, enabling architects, engineers, and other contractors to understand the layout, elements for fabrication, and more. As a matter of fact, shop drawing offers significant perks in the AEC project, as follows;

Advantages of Shop Drawing Service

Improved communication and coordination

Enhanced efficiency

Streamlined fabrication

Higher quality outcomes

Accurate costing

Reduced errors

The list of benefits can be extensive for shop drawing services, but it may seem similar to design drawings, as each set of blueprints offers insights for AEC professionals and is significant for construction projects. However, there is a substantial difference between shop drawings and design drawings; let’s explore it in detail.

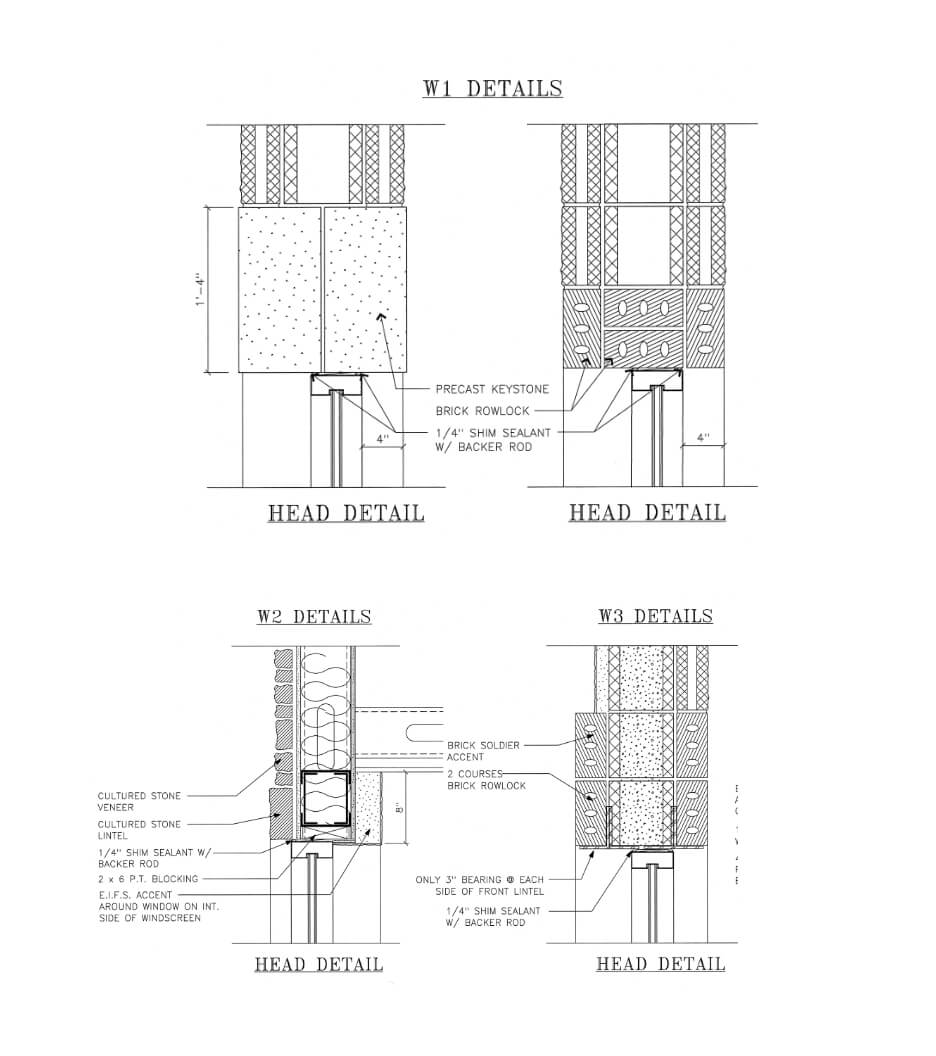

Shop Drawing Vs. Design Drawing: Major Difference

As briefly discussed, shop drawings and design blueprints offer a range of benefits and are essential for any architectural project, regardless of its nature or size. Each type of drawing serves a distinct purpose and plays a crucial role in ensuring precise, safe, efficient, and reliable construction processes. These drawings are used for 3D modeling, enabling AEC professionals to stay on the same page and understand the project’s design intent. As a matter of fact, shop drawing vs design drawing has been a crucial debate in the architecture and construction industry.

As they serve different purposes, it is notable to understand key differences. One offers an overall layout, style, aesthetic visuals, and project vision, while the other provides detailed and technical drawings, including dimensions, component locations, material properties, and more. Understanding the key difference between architectural drawings and design drawings can greatly enhance communication and collaboration among the design team, fabrication team, and execution team. The following states are the key aspects that differentiate one from another.

Factors

Shop Drawing

Design Drawing

Information Covered

As these are technical drawings typically curated by contractors or fabricators, it entails precise information for installation. Focusing on specific measurements, materials, properties, dimensions, fabrication details, installation requirements, and more, shop drawings ensure the design is accurately executed in terms of spatial requirements.

Compared to shop drawings, design sketches, or blueprints, architects usually curate them to focus on the creative outlook of the project and present their aesthetic vision. These drawings include floor plans, sections, elevations, and other visual representations to show how the final space will appear. Based on the conceptual information, the design drawing offers the overall intent of the project design.

Purpose of Drawings

Due to the intricate detailing in the blueprint, these are considered practical documents to ensure the design is translated into the construction process seamlessly and precisely. Moreover, these technical documents are vital for contractors and fabricators, as they provide detailed information for the precise assembly and installation of components into the project, minimizing potential errors and clashes.

As discussed, the primary purpose of a design drawing is to accurately communicate the designer’s vision, acting as a visual guide for the overall layout, spatial relations, and aesthetics of the project. Such drawings are included in the project’s brochure, client presentation, and for project approval before on-site construction begins.

Professionals Creating Drawings

The detailed and technical blueprints of the projects are often curated by skilled draftsmen or contractors to ensure the design feasibility and reliability in the projects. Draftsmen are well versed with process and experts in software technologies, ensuring all the components of the project meets the design intent and according to budget requirements. As MEP shop drawing services are critical, AEC firms tend to be outsourced by a reliable BIM company with significant expertise in shop drawing services.

As these types of drawings do not contain technical information, they are usually curated by architects, engineering design experts, or occasionally interior designers. Professionals aim to represent the project’s functionality, aesthetic appeal, and final look, which reflects the designer’s vision while also meeting the client’s demands.

Accuracy and Efficiency

Technical sketches demand utmost precision, detail, dimension, and material properties for construction projects. A simple error in the shop drawing can lead to costly outcomes in fabrication and during installation.

For design drawing, accuracy and efficiency pertains in layout for representing actual visualization of the project.

These are the major factors that influence shop drawings and design drawings, reflecting both differences and importance in the architecture and construction industry. As a matter of fact, each plays a crucial role for AEC professionals and contributes to the project’s success. At its core, each drawing aspect provides information for 3D modeling and the seamless execution of the project.

While a design drawing conveys the intent, a shop drawing provides detailed specifications of the components and their assembly. As these are critical processes that require expertise, outsourced shop drawings are the key solution for AEC firms to execute projects accurately. Outsourcing service providers ensure precision and efficiency in the blueprints by leveraging the right technology. UniquesCADD is a top BIM company in India, offering seamless shop drawings as well as design drawings by a team of professionals.

Final Takeaway

In the field of architecture and the construction industry, the importance of shop drawings and design drawings lies in facilitating a seamless construction process, ensuring the accurate fabrication, assembly, and installation of components.