Rahul Dogra

Rahul Dogra

Key Elements in MEP Shop Drawings for Effective Execution

Rahul Dogra

Rahul Dogra

Send Us Your Requirement

The modern architecture and construction industry’s accuracy, precision, and efficiency are the pillars of success. In the traditional days, there were significant aspects, but the process was complex due to a manual approach, a majority of risk factors, a long working process, the insignificant use of resources, delays in projects, and more.

All these become significant factors in the AEC project completion. As technological advancements and the continuous growth of the architecture and construction realm have evolved, AEC professionals have found ways to ease complexity and enhance project outcomes. Over the years, the architecture and construction sector has witnessed drastic changes in methods, approach, technology, and more.

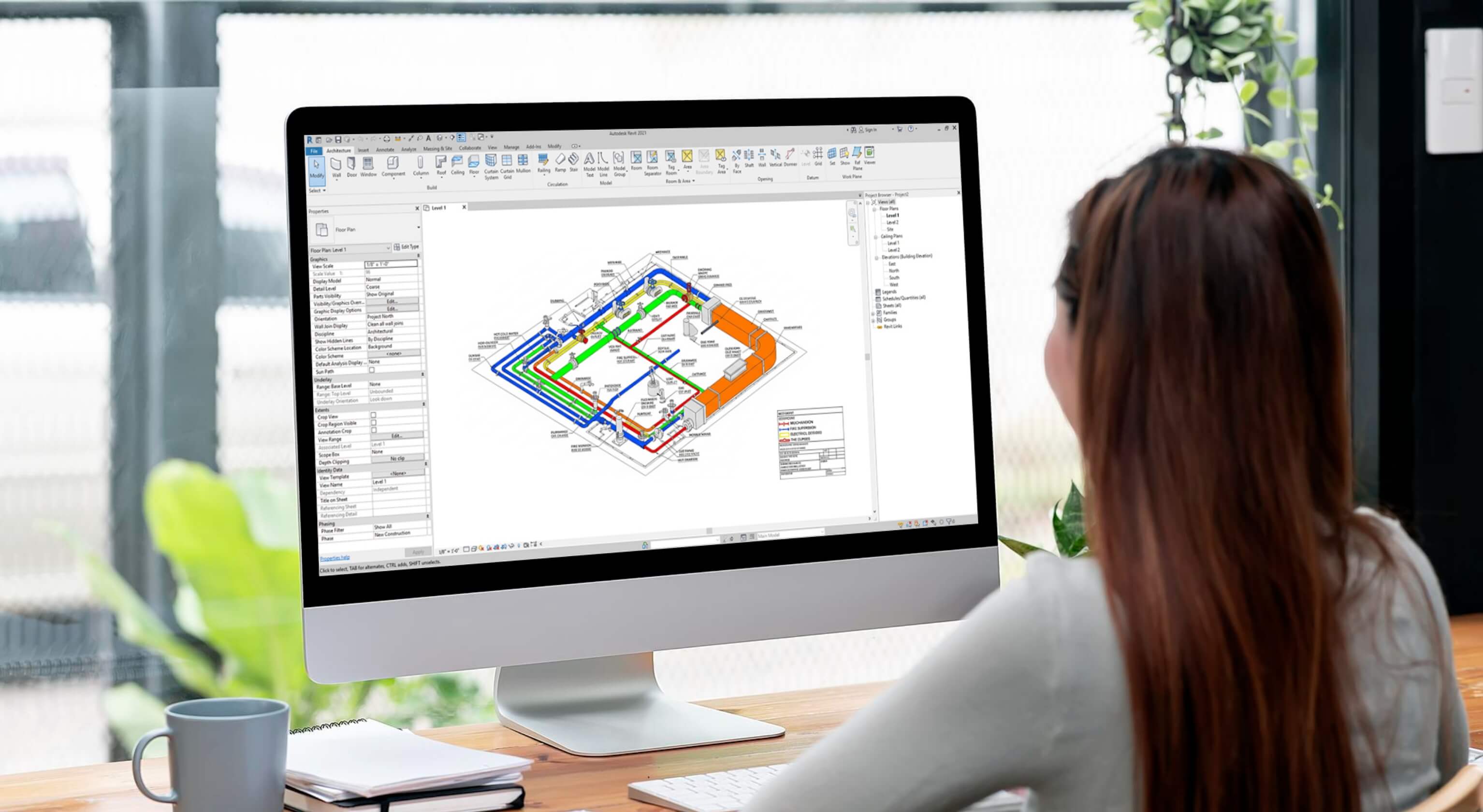

Thanks to building information modeling, which has provided architects, engineers, designers, and contractors a seamless way to maintain project quality and accuracy. Today, every construction project achieves accuracy and efficiency through the latest technology and a profitable approach. In every architecture project, different stages demand acute accuracy.

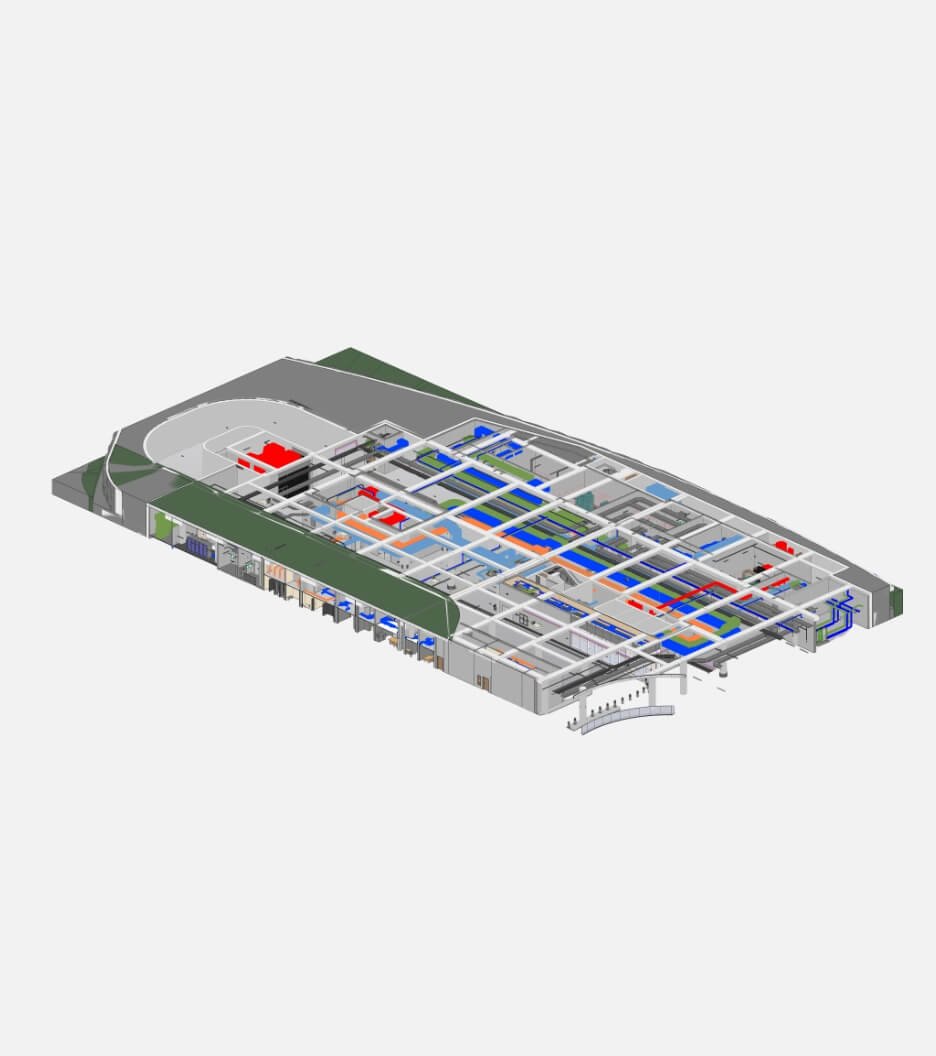

As a matter of fact, MEP is the heart of any project, regardless of size and nature, that demands the most precision. Typically, the concept of MEP turns the infrastructure into a functional building with proper electricity distribution, water supply, enhanced air ventilation, and more.

All these factors make any construction project functional and create a comfortable living environment. As MEP consists of three different disciplines, its accuracy, efficiency, and harmony are evident for all three elements to function together and maintain the safety standards for construction as well as occupants.

Therefore, MEP shop drawing services help maintain precision and enable MEP engineers to create detailed drawings for accurate component installation. These drawings are technical and serve as a blueprint for the construction process. Let’s understand in detail about MEP shop drawing and their elements for precision, safety, and success of the project.

Key Role of MEP Shop Drawings

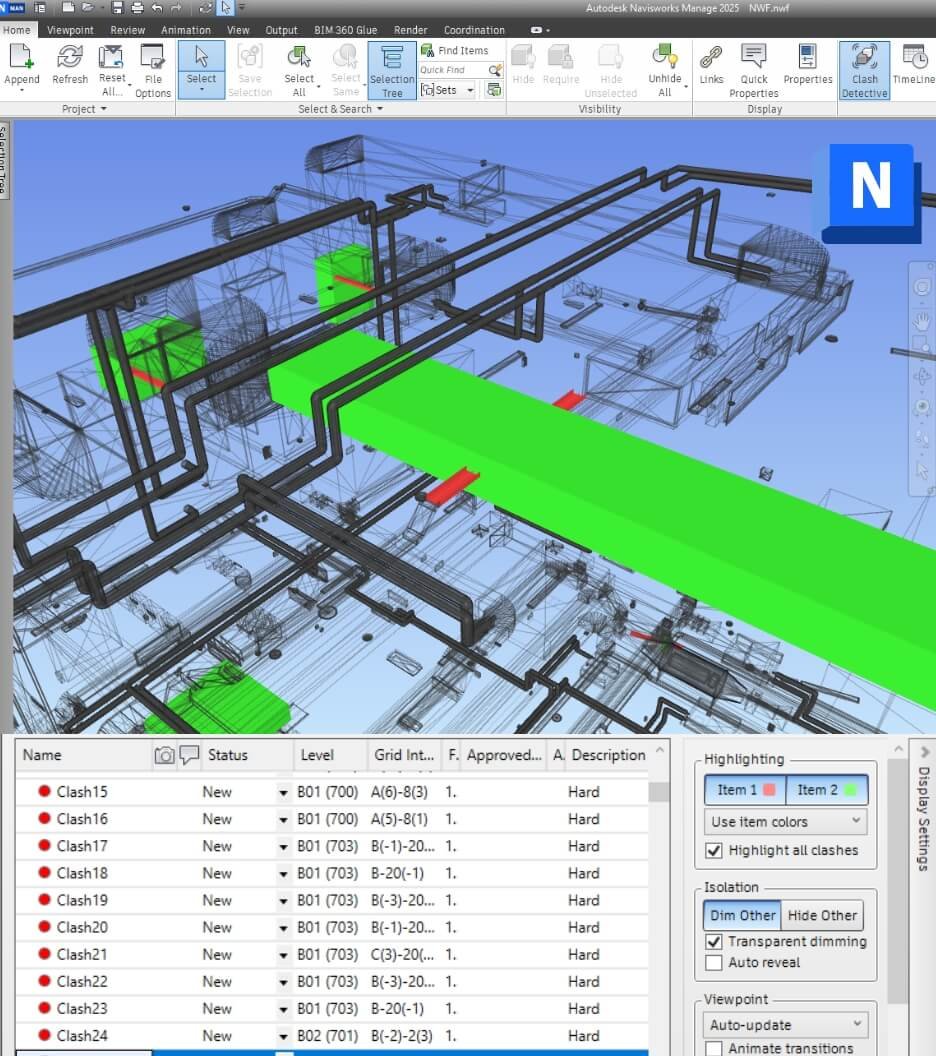

As discussed, the AEC realm has made significant progress in precision and high quality, thereby eliminating the scope of errors and risk. Shop drawing services have become a significant player in the modern architecture and construction realm, offering detailed views of technical drawings along with essential information required for complex stages. These drawings are typically for every component in the project but carries a great significance for effective MEP execution. MEP (Mechanical, Electrical, and Plumbing) shop drawings are a critical approach and act as a bridge between design and construction by AEC professionals.

These technical, detailed sketches serve not only as a basis for the architect’s plans but also provide detailed, fabricator-level instructions that ensure a project’s MEP systems are installed correctly, safely, and efficiently, in accordance with established standards. While design drawings show what needs to be built, shop drawings elaborate on the idea of effective MEP components execution and explain how it will be built under what measurements.

Usually, these technical, detailed drawings are prepared by contractors, subcontractors, or suppliers and approved by the design team to ensure compliance with the original design idea. This helps to maintain the communication, collaboration, and harmony between all three disciplines. The quality and accuracy of these drawings can significantly impact a project’s timeline, budget, and overall success. The following are some of the key benefits of MEP shop drawing services;

- Early clash detention

- On-ground streamlined process

- Detailed understanding of components

- Accuracy and efficiency

- Eliminates the scope of errors

- Saves time and project cost

- Communication and collaboration

These benefits highlight the importance of shop drawings and how crucial it is to maintain accuracy. As a matter of fact, MEP drawings must be properly coordinated to ensure a seamless workflow and synchronization between all disciplines. Additionally, this role involves not only coordination but also representing MEP drawing standards for MEP engineers, contractors, fabricators, and other professionals.

Upscale Architecture Project with MEP Shop Drawing

Get a Quote

These drawings demand keen attention as well as skills for utmost accuracy and efficiency. Typically, technical drawings of MEP include a variety of elements that make it effective for streamlined operations, managed deadlines, and safety on site construction work. Here are some of the key elements of MEP shop drawing that are crucial for completing the technical aspect.

Core Components of Effective MEP Shop Drawings

The importance and significant benefits of MEP drawings underscore the crucial nature of these services. Although the process entails some key elements that contribute to the success of MEP drawings. Since MEP is the heart of any construction project, it is vital to ensure the technical drawings are available to fabricators, MEP engineers, and other professionals.

For MEP shop drawings to be effective, it must be meticulously prepared and include several key elements. These components provide the necessary information for a smooth workflow, from fabrication to installation, bringing success to the construction project.

Components of MEP Shop Drawings Services

Project and drawing identification

Detailed layouts and plans

Electrical Drawings

General and project-specific notes

Mechanical (HVAC) Drawings

Plumbing Drawings

Comprehensive equipment and material lists

Project and drawing identification

Every shop drawing needs a clear and consistent identification system. This is the foundation of an organized project, helping professionals stay updated with the information. This may include;

- Title Block: A standard title block is essential for effective shop drawing for MEP. Usually, it includes the project name, location, drawing title (e.g., “HVAC Ductwork Plan – Level 2”), drawing number, revision number, date, and the names of the contractor, designer, and client.

- Drawing Numbering System: A logical and consistent numbering system is crucial for easy reference and retrieval. This system often uses a combination of letters and numbers to indicate the discipline (e.g., M for Mechanical, E for Electrical, P for Plumbing), floor level, and a sequential number.

General and project-specific notes

Notes provide vital context and instructions that aren’t easily shown graphically. They are often the first thing a reviewer or installer looks at. As these instructions offer detailed insights, professionals require specific notes to ensure the quality of the material or the equipment.

- General notes: These cover universal project standards and specifications, such as safety protocols, material requirements, and general installation practices.

- Key Plans and legends: A small-scale key plan helps orient the viewer to the drawing’s location within the larger building. Legends clearly define all symbols, line types, and abbreviations used in the drawing.

- Specific notes: These are unique to the drawing and its specific scope of work. They might include instructions on equipment placement, special clearances, or specific connection details.

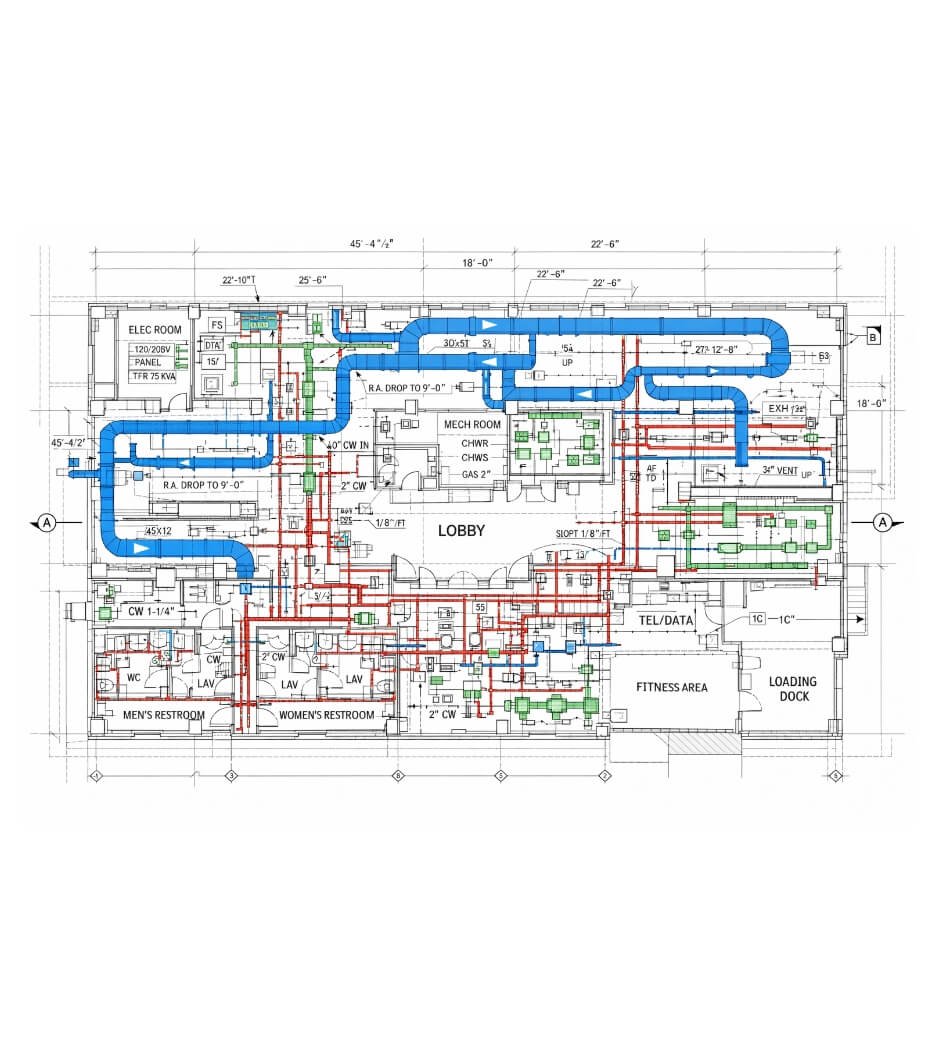

Detailed layouts and plans

This is the heart of the HVAC electrical plumbing shop drawings. It graphically represents the system’s layout and configuration, along with other details that reduce the scope of errors and streamline the accuracy. This may include the following information.

- Scaled drawings: All layouts must be drawn to a specific, accurate scale (e.g., 1/4″ = 1′-0″). This allows for precise measurements and ensures components will fit within the allocated space.

- Floor plans: These drawings show the horizontal layout of the MEP systems, including the location of pipes, ducts, conduits, and equipment. They should be coordinated to show all disciplines on the same drawing or a coordinated composite drawing to avoid clashes.

- Sections and elevations: Cross-sectional views and elevations are critical for showing the vertical relationships of components, especially in complex areas like shafts, mechanical rooms, or ceiling plenums. They provide a clear understanding of how systems stack and interact.

Comprehensive equipment and material lists

A detailed list of all materials and equipment is necessary for procurement, quality control, and installation of the MEP components. From HVAC equipment to quality water pipes, all must be of high quality for maintaining longevity as well as safety.

- Bill of Materials (BOM): A BOM lists every component needed, including pipes, fittings, valves, ducts, conduits, and fixtures. It should include the quantity, size, material, and a clear description for each item.

- Equipment Schedule: This schedule provides detailed information on all major equipment, such as chillers, air handling units, pumps, switchgear, and panelboards. It should include the manufacturer, model number, dimensions, weight, power requirements, and any special installation notes.

- Discipline-specific requirements: While many elements are universal, each MEP discipline has unique requirements that must be addressed in its shop drawings.

Mechanical (HVAC) Drawings

- Ductwork Layouts: This showcases the complete path of supply, return, and exhaust ducts, including duct sizes, materials, insulation types, and locations of diffusers, registers, and grilles.

- Piping Schematics: Detail the layout of hydronic, refrigerant, and condensate piping, including pipe sizes, material types, valves, pumps, and insulation.

- Equipment Connections: Provide specific diagrams for connecting equipment like air handling units, fan coils, and boilers, showing all power, control, and piping connections.

Electrical Drawings

- Power and Lighting Plans: Show the location of all electrical equipment, including panelboards, switchgear, light fixtures, outlets, and switches.

- Single-Line Diagrams (SLDs): These are simplified drawings that show the electrical system’s path, from the service entrance to individual panels and major equipment. They are crucial for understanding the system’s logic and are essential for commissioning and maintenance.

- Wiring Diagrams: For complex control systems, a wiring diagram shows the connections between components, relays, sensors, and the control panel.

Plumbing Drawings

Show the routing of all domestic water, sanitary waste, vent, and storm drainage piping. Include pipe sizes, slope requirements, cleanouts, and the location of fixtures and risers.

- Isometrics: Isometric drawings are often used for plumbing to show a three-dimensional view of the piping runs. This is particularly helpful for complex piping assemblies and allows for easier visualization and pre-fabrication.

- Riser Diagrams: These drawings show the vertical distribution of plumbing systems, from the basement to the roof, indicating the size of risers and branches.

The mentioned shop drawing checklist is vital for the success of the project. As a matter of fact, it helps to assure the quality of the equipment, prevent design issues, minimize potential errors, and more. However, MEP coordination drawings depict the seamless installation of all three components without any clash.

Coordination among the MEP disciplines increases the building’s longevity and safety for occupants as well. Therefore, the role and key components of Revit MEP drafting services are not only evident but have become an indispensable approach for AEC professionals for a project’s success. Due to technicalities in the approach, MEP shop drawing demands precision and efficiency with the use of the latest technology. Look further, how partnering with a shop drawing service provider can be a wise choice.

Outsource Shop Drawing for MEP

MEP drawings in construction help improve project coordination and communication among AEC professionals. However, as mentioned, shop drawings are technical, detailed sketches that require specialized skills, expertise, and proficiency with software and more. As a matter of fact, AEC firms lack the expertise and technical software necessary for achieving accurate outcomes. Having an in-house team can be expensive for an AEC firm, as it entails hiring the required talent, investing in technology, and managing time-consuming training and development, infrastructure development, and more.

All this is an added expense in the AEC firms, whereas professionals look for ways to cut costs. Moreover, having an in-house team is also risky as it is difficult to keep updated with trends, technology, and changing market demands. To overcome such challenges, outsourcing MEP shop drawing services is one holistic solution. Outsourcing with reliable and top MEP service providers brings enhanced benefits and maintains accuracy. The following are some of the key perks of outsourcing shop drawing services.

- Cost efficiency

- Tailored solutions

- Expertise knowledge

- Technology proficiency

- Accurate and efficient solutions

- Customer support

These are some of the benefits of outsourcing MEP shop drawings by a top service provider. UniquesCADD is a top BIM company with significant expertise in MEP shop drawings. With a team of professionals and the use of cutting-edge technology, UniquesCADD offers premium, accurate, and cost-efficient industrial experience.

In the End

In the modern architecture and construction industry, MEP shop drawings hold a pivotal position for assuring streamlined workflow and efficiency in the MEP system installation. From fabrication to on-site ground work, shop drawing services help in attaining accurate MEP solutions and result in project success with safety standards.