Moin Khan

Moin Khan

Why Contractors Depend on Accurate MEP Shop Drawings for Project Success

Moin Khan

Moin Khan

Send Us Your Requirement

The construction and architecture industry involves a range of complex processes that demand attention and precision. Over the years, digital transformation in the AEC landscape has led to simplified processes, on-time project completion, cost control, and more. Eliminating traditional practices and adopting a technological approach has drastically altered how architects, engineers, contractors, and other professionals work.

From time-consuming processes to time-efficient approaches, the AEC landscape has evolved. With the constant evolution of technology and innovation, AEC experts seamlessly complete construction projects and ensure their safety, precision, and efficiency. As a matter of fact, for every small or big project, MEP is the most critical as well as the most complex part.

In the construction landscape, MEP ensures a comfortable and livable environment within the building, providing basic functionalities. MEP stands for mechanical, electrical, and plumbing components, and in modern days, fire safety is an added element (abbreviation F). Each component serves a critical role in creating a comfortable environment for occupants, such as equal electricity distribution, good ventilation, accurate AC ducts, seamless water flow and drainage, effective fire safety precautions, and more. It is essential to ensure harmony and synchronization among all components to enable them to work collaboratively and bring efficient building functionality to life.

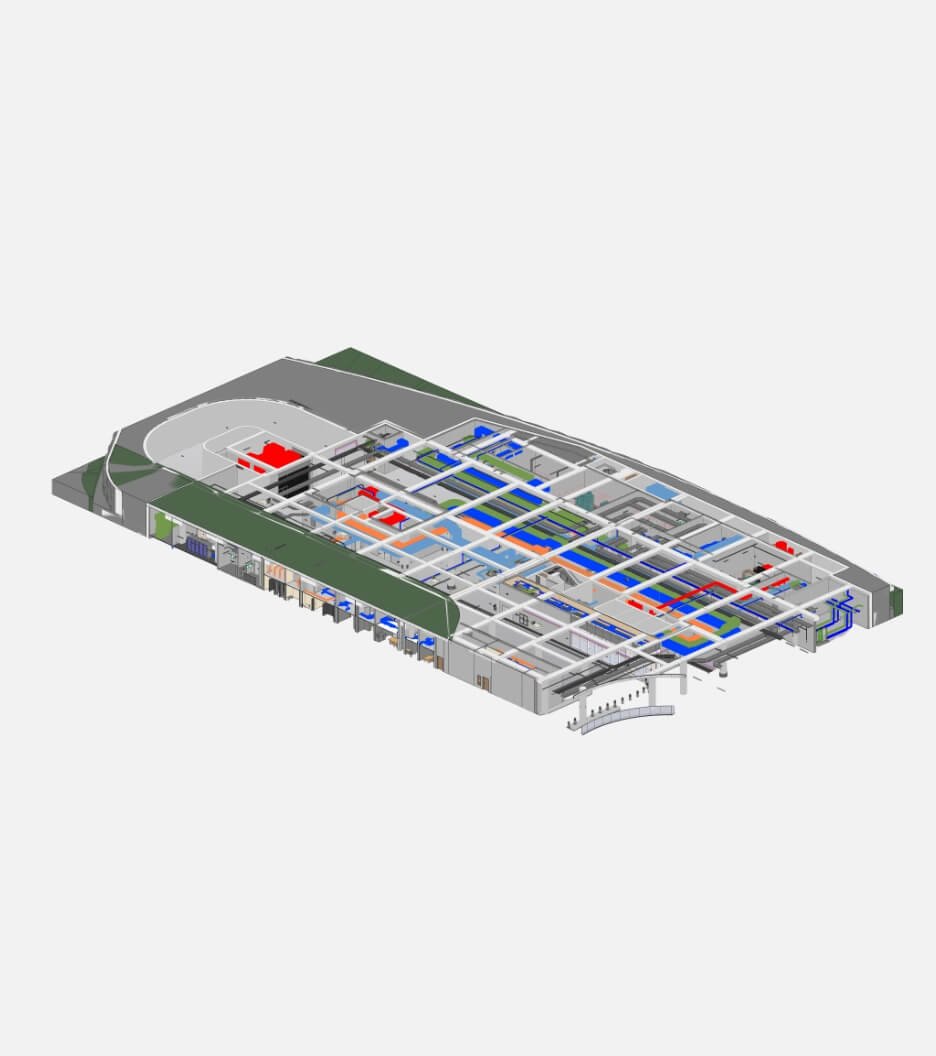

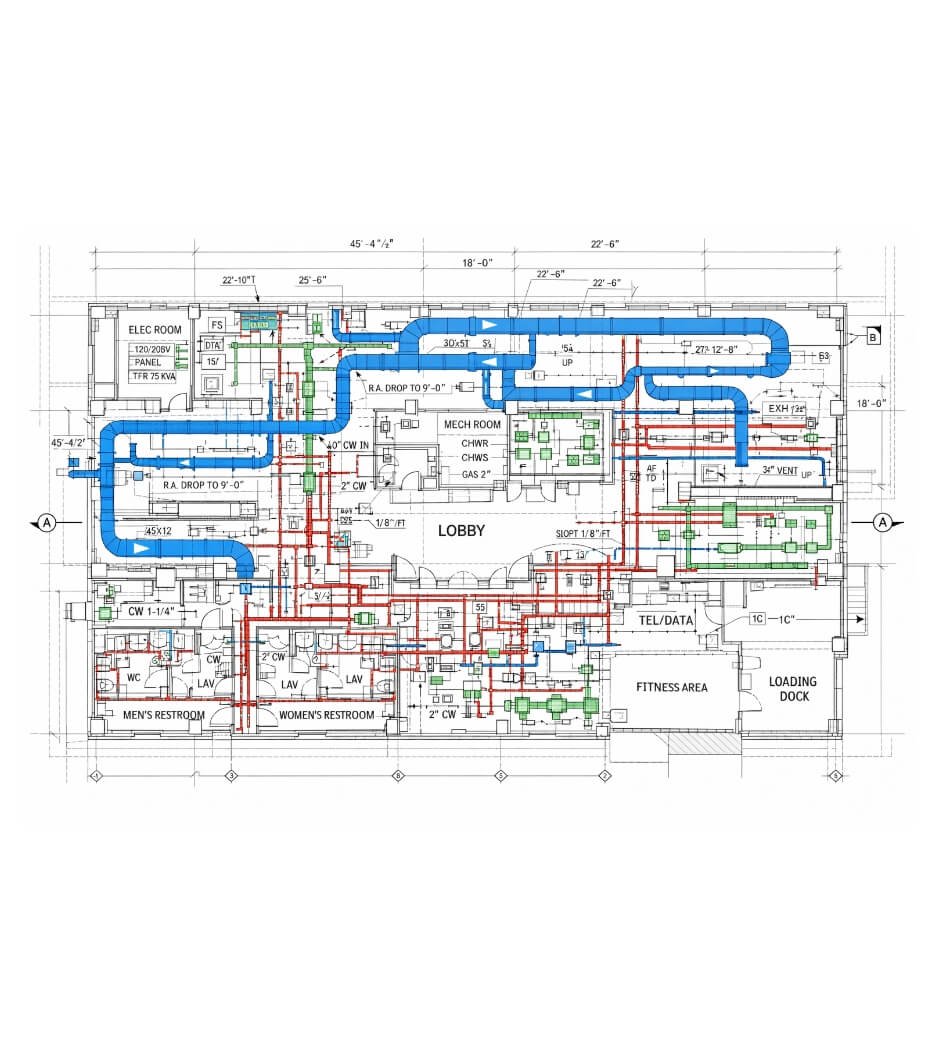

Nonetheless, in the long and critical construction project, MEP component installation is the most time-consuming as well as complex aspect. As a matter of fact, being an essential aspect in the construction, it is evident to create detailed sketches or drawings of the MEP components. This includes detailed dimensions, location, and geometry of the elements that enable MEP engineers as well as contractors to understand the coordination between all three components. Here, the role of MEP shop drawings services comes into play, which allows AEC experts to have a detailed view of how all the components will synchronize together and act in the BIM model.

Detailed sketches help contractors understand the complexity of integration and ensure a seamless workflow in the project. In the vast realm of architecture and construction, MEP shop drawing is a complex subject to understand. Let’s explore in detail how MEP shop drawings in architecture and construction help contractors achieve project success.

MEP shop drawing for seamless project completion

Talk to Us

Key Insights to Accurate MEP Drawings

Construction project success heavily relied on precision and efficiency and seamlessness in the infrastructure’s functionality. Any construction building consists of generic functionality that makes a comfortable and livable environment for occupants. From equal electricity distribution to proper air ventilation in the building, every aspect is important.

Here, MEP BIM services play a prominent role; however, to ensure these components, along with fire safety, are coordinated and synchronized in the model is evident. MEP shop drawings are a game-changer for AEC professionals and contractors. In the constantly evolving landscape, detailed drawings and sketches enable professionals to understand the complex system and its installation in the design.

Today, MEP shop drawing services have become an invaluable tool for building contractors, assuring the seamless installation of the design without any clashes or significant changes. The shop drawing concept quickly gained popularity in the AEC industry, enabling the coordination of MEP systems within the building model. These detailed drawings and diagrams provide a comprehensive view, ensuring smooth project execution and achieving the desired outcomes. As a matter of fact, accurate MEP drawings are a crucial step that supports a streamlined installation process.

These detailed drawings contain critical information, including materials, installation details, and required equipment, which enables the seamless execution of the project. Moreover, shop drawing helps to enhance coordination between contractors and other AEC experts. Detailed MEP drawings serve as a guide to contractors, allowing them to visualize how different components will be integrated into the design in harmony.

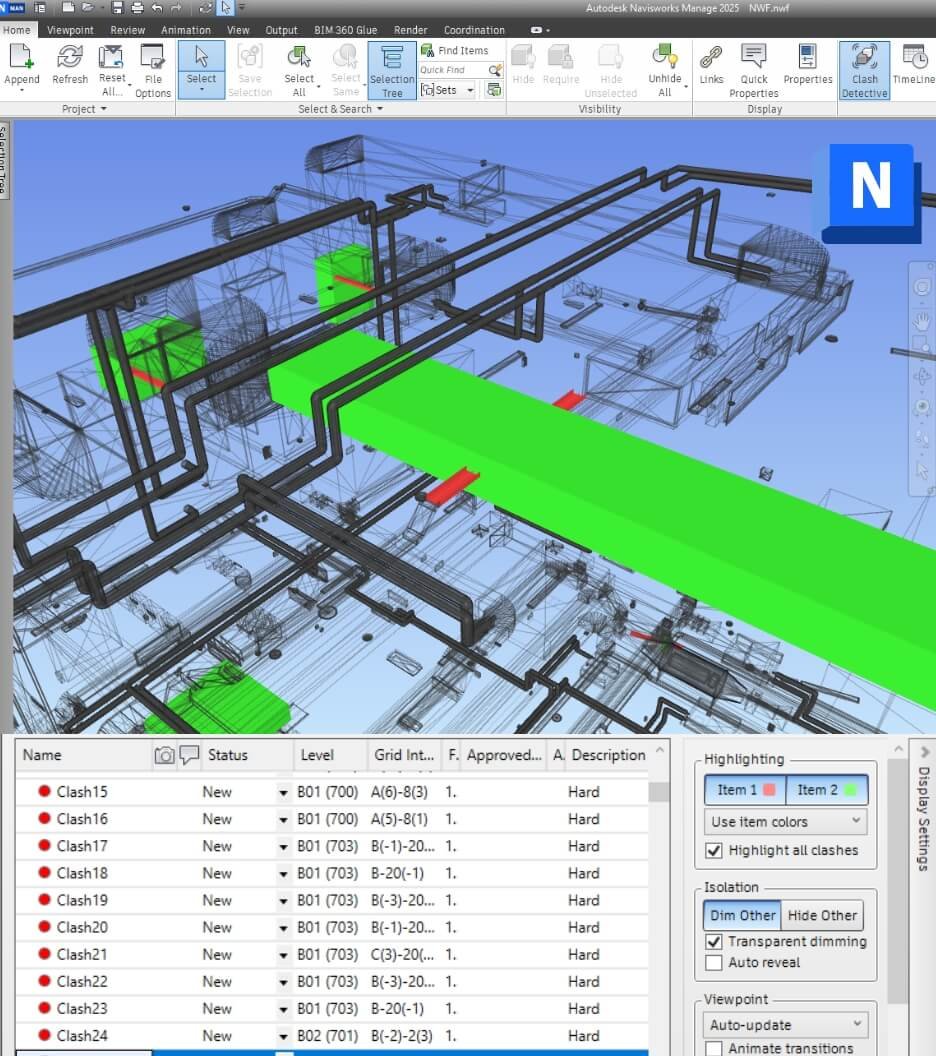

MEP design and drafting also help in identifying potential issues or clashes in the design before the construction begins. This eventually prevents cost rework, delays in project execution, and ensures seamless execution. Not only this, but these drawings are also a vital part of construction documentation services, offering numerous benefits, as follows;

- Reduced errors, clashes, and conflicts

- Ensures clarity and accuracy

- Prevents delays and costly rework

- Streamlined project management

- Key insights for facility managers

These benefits are only a glimpse of the significance of MEP shop drawing services. While being evident for any construction projects, they are apparent to contractors and other project stakeholders. Let’s discover in detail how MEP installation drawings are useful for contractors.

MEP Shop Drawing for Contractors

In the complex world of architecture and construction, the significant role of the MEP element is most evident. Its harmony and precision lead to project success and the safety of occupants. To ensure the seamless integration of MEP components in the design, MEP shop drawings are a crucial role player. As discussed briefly, shop drawing in construction are a critical aspect, providing a variety of benefits for complex stages. These drawings serve as a blueprint for the accurate fabrication and installation of MEP components in the infrastructure.

Not only this, but MEP drawings are more than just technical sketches; they are a detailed representation of each component, complete with accurate dimensions and other relevant geometry. Moreover, it also showcases the design intent, assembly instructions, and complex system interconnections that lead to streamlined project execution.

While there are numerous AEC professionals involved in the single project, contractor coordination in MEP system integration is evident. In any architecture project, contractors leverage the power and reap some benefits of MEP construction documentation services. These technical, detailed sketches serve as a blueprint for complex pipes, wires, and equipment.

As a matter of fact, for contractors, MEP drawings help to streamline workflow and stick to standard codes. Without MEP shop drawings, contractors face critical challenges in the project that can increase the scope of errors and may delay the completion. The following are the significant challenges faced by contractors without the implementation of MEP shop drawings.

- Coordination issues

- Complexity in system integration

- Compliance with regulation

- Budget and cost management

- Sustainability and energy efficiency

The challenges mentioned above are faced by contractors, which also reflects the significant importance of MEP design and drafting services. As a matter of fact, these are also used by facility managers to maintain the project lifecycle. Explore in detail why contractors must adopt MEP technical drawings.

Importance of MEP Shop Drawing for Contractors

As discussed in detail about the significance of MEP drawings and the challenges faced by contractors for skipping drawings. For accuracy, efficiency, and above all, safety for occupants, MEP integration in the design must be flawless to avoid any clashes or conflicts at later stages of construction. Traditionally speaking, drawings have been a key part of the construction process. Professionals earlier used to hand draw the sketches with utmost accuracy however there were chances of human errors.

These errors occurred during on-site construction, resulting in inaccuracies, project delays, overbudgeting, and other issues. While technology and innovation gradually altered the vast sector, MEP coordination drawings played an evident role for all the AEC professionals and especially for contractors. The following are some of the key reasons that showcase the importance of MEP drawing accuracy for contractors and serve as a solution to the above challenges.

Significance of MEP Shop Drawing for Contractors

Clarity and coordination

Better project planning

Accurate fabrication

Material estimation

Desired assurance

Construction documentation

Improved communication and collaboration

- Clarity and coordination: In the field of AEC, technical drawings and sketches serve as a guide to understand the location and interrelationship of different MEP components. Integration of MEP systems into a single design plan can lead to errors or clashes. However, with accurate MEP drawings, these clashes are eliminated, and contractors can minimize the costly delays and rework during the construction phase.

- Material estimation: For MEP systems to be integrated into building designs, a variety of materials in precise quantities are required, including pipes, wires, fixtures, and other equipment specific to the project. Accurate sketches of MEP elements enable contractors to precisely manage material estimation and budgeting for projects, as these detailed sketches provide to-the-point measurements, specifications of each component, and other relevant geometry, allowing for precise material cost estimation. This also contributes to minimizing waste and optimizing project cost.

- Improved communication and collaboration: Effective communication and collaboration are key factors in ensuring project success. While AEC projects consist of various phases, each stage demands for seamless communication and coordination. MEP shop drawing facilitates clear communication between various AEC professionals as they represent complex systems in detailed aspects. Furthermore, these technically drawn sketches foster teamwork, eliminate miscommunication, and offer streamlined construction processes.

- Better project planning: Another key aspect of MEP installation drawing is seamless project planning. These detailed sketches provide a comprehensive overview of MEP systems, from installation locations to interrelationships. With such details, contractors can plan project completion, schedules, resource allocation, and more beforehand. As a matter of fact, this is considered a proactive approach, which results in efficient planning of projects and on-time project completion.

- Desired assurance: In the AEC industry, sticking to design intent and building codes is evident for overall project assurance. With the help of MEP shop drawing services, these technical document services serve as a benchmark for quality assurance in the project. These technical drawings are reviewed by contractors for thorough checks, inspections, and quality control to minimize the scope of errors and ensure high quality in projects.

- Accurate fabrication: For MEP to be successful, one of the major aspects is the right and accurate fabrication of MEP components. While technical sketches offer precise detailing of elements, these are used by fabricators to ensure the accurate fabrication of MEP equipment for the projects. Contractors utilize technical drawings to minimize on-site labor requirements, expedite the construction process, and maintain high-quality standards.

- Construction documentation: the concept of technical detailed drawing helps in construction documentation. As a matter of fact, construction documentation services consist of MEP drawings that serve as a detailed data document for facility management, future expansions, renovations, and more.

The above-mentioned highlights explicitly the importance as well as solutions to the discussed challenges. MEP shop drawings are a crucial part of any AEC project, regardless of size and nature. Nonetheless, these technical drawings for MEP enable professionals to streamline the complex process of MEP services, which serves as the heart of any infrastructure.

With precise drawings, it helps ensure the efficiency and accuracy necessary for overall project success. However, accurate MEP drawings require the right use of technology, skills, and being well-versed in the process, among other things. This calls for outsourcing MEP shop drawing services by reliable companies. Here are some insights into outsourcing shop drawing services and their benefits.

Outsourcing MEP Shop Drawing Significance

The AEC landscape is constantly evolving in response to technological advancements and innovation. For AEC firms, it is challenging to keep pace with technological advancements and continually upgrade their systems. While MEP is the most critical aspect of building design, serving as the heart of infrastructure, ensuring that the most accurate drawing is vital.

Partnering with a reliable outsourcing service provider for drawing is a comprehensive solution, as outsourcing firms typically have a team of experts and access to the latest technology. AEC firms nowadays heavily rely on outsourcing service providers to achieve accurate project outcomes, allowing the firm to focus on core activities and enhance overall productivity.

Shop drawing outsourcing companies are experts in MEP shop drawing and understand the complex nature of the process. Hence, with the right technology, a team of shop drafters ensures precision and technical details in the drawings. Partnering with the right outsourcing MEP shop drawing service providers offers various benefits, such as;

MEP Shop Drawing Outsourcing Services

Streamlined process

Expertise knowledge

Project support

Access to technology

Quick turnaround

Cost efficiency

These are some of the benefits of outsourcing MEP drawings. UniquesCADD is a top BIM company with specialization in shop drawings, including structural, architectural, and MEP. With a team of experts and the utilization of the right technology, UniquesCADD aims to deliver MEP shop drawings with precision and quality.

Concluding Remarks

In the AEC industry, efficiency and precision are paramount to success. Each construction process must be accurately completed for the overall success of the project. MEP being critical, MEP shop drawing services enable contractors to ensure project efficiency.